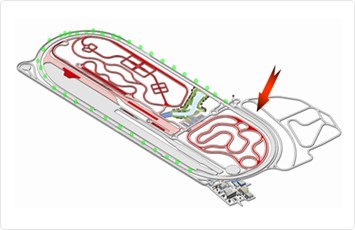

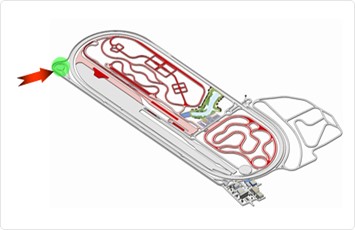

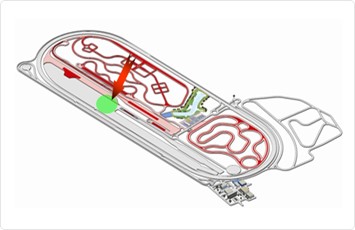

PG(Proving Ground)

Driving course facility

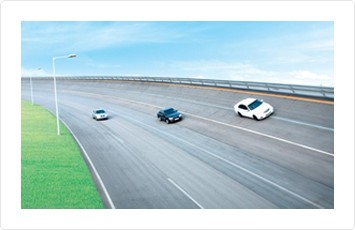

High-speed main circuit

Main Tasks

It is in an elongated oval shap. One rotation length is 5,040m. Road width is 16.2m and is compose of 4 lanes of asphalt. When driving through the circular curve, the transverse centrifugal force does not take effect and the angle of the circular circle vortex is approximately 42° so it is designed to be able to control without a handle at a certain constant speed (approximately 180km). There are 2 straight sections and 2 circular curve sections and the designed maximum sapped for maximum safety that is possible for driving is 250km/h.

Facility and Data

- Specifications: 5,040m× 15.2~19.5m (oval)

- Longitudinal: straight section 967m×2, alleviation section 411×4, curve section 731×2

- Transverse: straight section 15.2m(4.0/3.6/3.6/4.0), curve section 19.5m (5.5/5.0/5.0/4.0)

- Radius of curve 360m

- Maximum angle 42°

- Maximum speed 250km/h(designed speed 180km/h)

Facility Usage

Maximum speed test, acceleration capacity test, speedometer test, constant speed fuel consumption rate test, high-speed brake test, high-speed endurance test, riding comfort while high-speed driving, wind noise evaluation test, tire durability evaluation, steering performance evaluation, air conditioner performance test, cutting-edge futuristic vehicle, ACC development test, ITS performance evaluation test, etc.

Main Tasks

- The straight road and moist test track's straight section is a dry asphalt test track of 1.8km composed of two lanes with two straight line tracks and circular racks at both ends. There is a noise test track certified by ISO that can measure the driving noise of the vehicle at the center of the straight track.

- Radio disturbance testing site (EMC test site) is an outdoor electrowave test site and within a 30m radius of the measuring environment, there are no electromagnetic reflectors and it is fit for EMI specifications. The electrowave reflection test and development test are carried out in free battlefield status.

Facility and Data

- Straight Road and Noise test track

- Specifications: 3,963m× 8m (Open-type 2 lanes)[longitudinal: straight 1 1,802m, reverse 1 183m, straight2 1,532m, reverse2 446m, transverse: straight1 3.5/ separator 1.0/ straight23.5]

- straight road, test track (background noise 10㏈ difference/ dense asphalt packaging)

- EMC test site

- Specifications: diameter 60m, within ±4㏈, 18㎓radiation/ steel plate(18m×21m) / turntable diameter 5m, 360° rotation / receiver (ES126), antenna master, network analyzer, etc.

Facility Usage

- Straight Road and Noise test track - Ministry of Environment certification test, stop and overtake acceleration test, driving noise test, exhaust noise test, tire drifting noise test, drifting capacity test, horn noise test, etc.

- EMC test site - 10m electrowave radiation test, audio capacity evaluation test, antenna capacity evaluation test, etc.

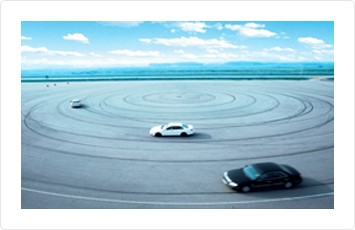

Main Tasks

- Universal road - This is a flat asphalt test track with a width of 64m and length of 900m. It is square-shaped in the form of a wide open square. Diverse integrated performances and legal testing can be conducted and it is connected to the rotating testing site so general performances of vehicles can be checked here through diverse brake safety evaluation test, steering safety evaluation test, tire trait test, and system flaw test, etc.

- Turning test track - This is a circular asphalt track of 100m and the concentric circle's level is consistently covered. Radius of 12m, 20m, 25m, 50m circular lanes are indicated to facilitate testing for diverse rotational and safety tests. When conducting dangerous test such as J-turn testing or rotational braking test, the surface must be checked for unevenness or gradient changes.

- Road safety facility evaluation site - The road safety facility evaluation site is 660m long, 150m wide and is composed of a fourway crossing, straight road, and curved roads. It is a testing site that is utilized for not only performance tests for crash barriers and viewing guidance facilities, but also domestic standards research. The curved testing road is 880m long and 9m wide and the round-trip 2-lane entrance way is 316m in curve radius. Driving up to 80km/h is possible. Performance tests such as for visual guidance facilities and non-skid pavement are possible.

Facility and Data

- Universal road

- Specifications: 900mx70m [Test road 64m, pavement shoulder 3.0/3.0]

- Rotating testing site

- Specifications: radius 100m, slip coefficient 0.75 or more / asphalt packaging [radius 12, 20, 30, 40, 50m circular lane indication]

Facility Usage

- Universal road

- general brake test, direction capacity test, tire rupture test, acceleration capacity test, noise vibration test, control safety evaluation test, lane change test, slalom test, etc.

- Rotational testing site

- Brake capacity test, ABS development test, tire trait test

- steering test, vehicle responsiveness test, steady-state steer test, minimum rotation radius test J-turn test, rotational brake test, etc.

- Road safety facility evaluation site

- crash barrier collision test visual guidance facility, road reflector, road electric light sign, non-skid pavement, safety facility for the disabled, speed bump, lighting facility, falling prevention facility performance evaluation test, road technology development test, etc.

Main Tasks

This is 700m in length and is composed of a 2-lane acceleration road and roads of different friction factors of 0.1, 0.3, 0.5, 0.7~0.8 that imitate icy, snowy, and rainy roads. Beside each road is a 1.5m asphalt (friction factor of 0.7) and in order to form a water test, sprinklers were installed on either sides. Normally new technology non-skid systems such as ABS (Anti-shock Brake System) can be tested in this facility and diverse traits of the tire can be tested here such as the sudden-brake test of 120km/h at friction factor of 0.3, the μ-Jump test in which there is a sudden-break at 120km/h from friction factor 0.7 to 0.3 road as in the case of suddenly driving on a snowy road from a wet road, as well as other split tests and diverse braking tests and wet road tests.

Facility and Data

- Specifications: ceramic 200m×4m, basalt 250m×6m, bridged pebble 200m×6.55m, wet asphalt/basalt 200m×4m

- Type: ceramic tile road (μ 0.1), basalt tile road (μ 0.2), bridged pebble road (μ 0.4), μ-jump road(μ 0.75→0.5)

Main Tasks

This is a test road with double-width test roads where it is possible to evaluate vehicles rotating at high velocity with driving stabilizing devices equipped, as well as other tests such as high-speed rotation driving safety, tire adhesiveness, and slip steering stability.

Facility and Data

- Acceleration section 950m × 27m

- Test section (basalt) 300m × 60(20)m

- Brake section 200m × 60m

Facility Usage

- ESC, TCS development test

- Fast motion velocity stability test (FMVSS)

- Tire adhesiveness test, etc. (ECE)

Main Tasks

This is a unpaved testing road of 2,100m with maximum width of 7. It is utilized for vehicle durability evaluation in harsh driving conditions. This reflects diverse offroad environments such as gravel roads, sand roads, and muddy roads. It is possible to evaluate the durability and vibration noise of general vehicles as well as military and special vehicles’ main frame and parts.

Facility and Data

- Closed-loop type unpaved road test road

- Length of 2,100m, width of 7m

Facility Usage

Parts durability, noise evaluation, endurance reliability test such as for main frame, control device parts, and bushing

Main Tasks

- Hill test track The hill test track where the vehicle’s gradability and parking brake capacity on hills can be tested. Test roads of diverse gradients are needed, but 12%, 20%, 30% sections were designed so that regulation tests can be conducted.

- Circular skid pad (Skid pad) This is a test track with a 100m radius covered with special concrete. Sprinklers are installed at the end of the test track and the concrete surface have been grinded to adjust the friction figure to 0.5. There is a water screen on the road and the curved radius is consistent. Tire traits test and steering traits tests such as understeering and oversteering can also be done.

Facility and Data

- Hill test track

- Specifications: 7×5.200m

- Category: 12% test track 15m×5m, 20% test track 10m×5m, 30% test track 5m×5m

- Circular skid pad

Facility Usage

Hill test track- gradability test, parking brake capacity test, etc.

Main Tasks

Tests on capsizing stability from sudden direction change and light distribution variable headlights are possible. This is where tests such as active direction device high-velocity driving stability.

Facility and Data

- Test track extension 4.067m

- Test track width 8 ~ 15m

- Turning radius 30 ~ 320m

Facility Usage

- EPS(Electric Power Steering), AFS(Active Front Steering) development test and evaluation

- Sudden direction change capsizing stability test

- Light distribution variable headlights test (ECE) etc.

Main Tasks

This is an automatic test track that takes into consideration the drivers’ accumulated fatigue and test repetitiveness where you can also check and develop test the stability of weight reduced main frames and loading of electric device.

Facility and Data

- Belgian road 1,200 × 4m

- Washboard road 200 × 4m

- Long-wave road 200 × 4m

- Torsion road 200 × 4m

- Model road 400 × 4m

- Submerged road 100 × 5m

Facility Usage

- High-mileage, main frame weight reduction endurance test, etc.

- Electric device shock test such as ESC, EPS

- Electric device and brake capacity test when submerged